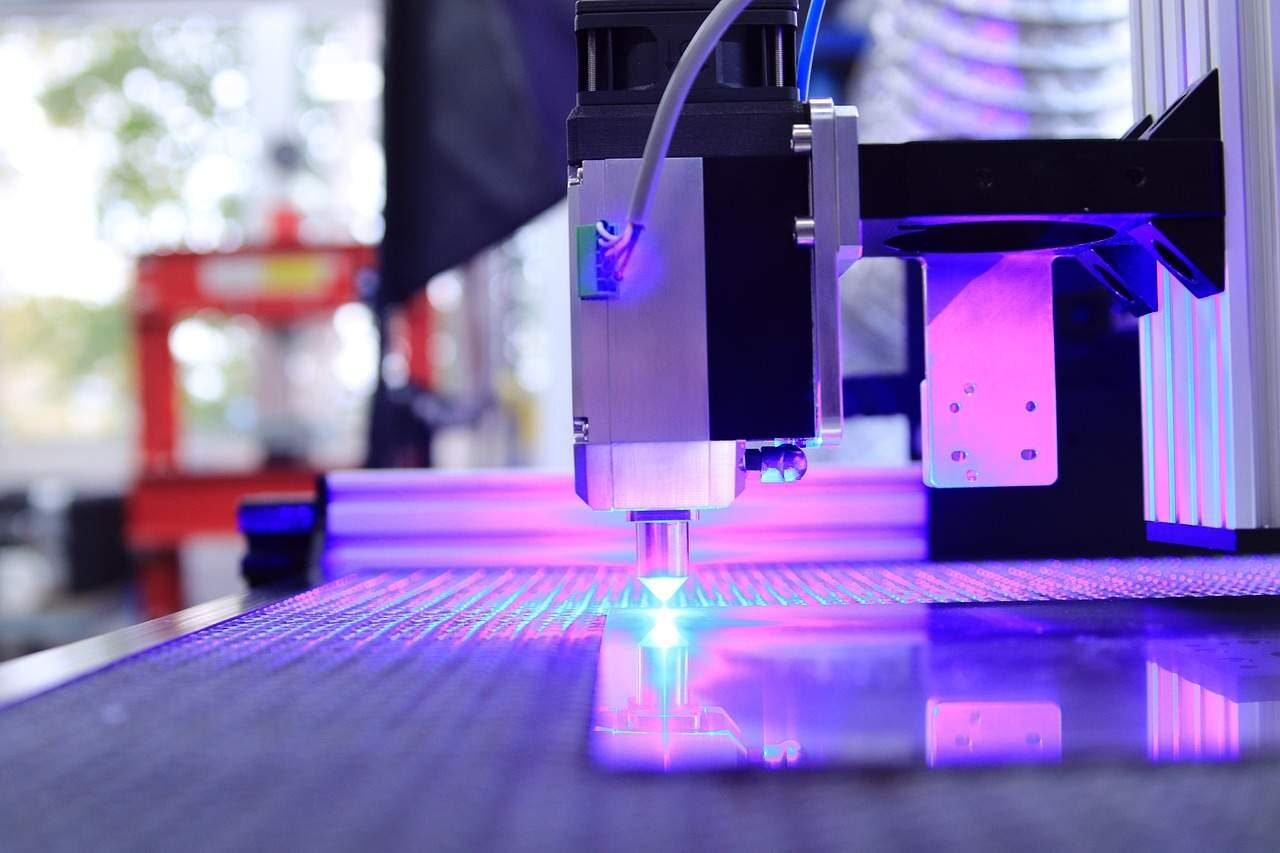

Laser marking and laser engraving machines they are the same thing? Laser marking and engraving stand often used, improperly, as synonyms while in reality; they refer to two similar processes but of a different nature. The laser beam in both processes imprints an indelible mark on material but the results obtained are different.

Here is the article to explain, How to define the Advantages of Laser Engraving Machines in the Industrial World!

The two processes differ precisely in the interaction with the material; in the marking, we have a process of physical transformation of the surface that generates a change in the permanent shade; while the engraving removes a surface layer of material, vaporizing it and creating an abrasion.

On this site https://www.lasitlaser.com/, you will find various information about the info described in this short article. Let’s analyze the 3 steps through which we “write” with the laser

1) The laser beam hits the surface of the material;

All laser marking or engraving methods have in common that the beam stands pulsed and releases energy at specific intervals. For example, a 100W laser releases 100,000 pulses in one second. Each pulse contains one millijoule of energy and can reach 10,000W of peak power.

To control the amount of energy emitted by the laser it is necessary to adjust the processing parameters. The most important ones are speed and frequency and – at the drawing level – the line spacing. In this way, it is possible to adequately manage the distance between the pulses to obtain the right combination between overlap (overlap) of the pulses and energy concentration.

With laser engraving, the pulses are much closer than with marking. Marking requires less energy than engraving and consequently is faster.

2) The material absorbs the energy of the laser beam;

The surface of the material absorbs and converts only part of the laser pulse energy into heat. For marking to carry out – based on the type of material and marking required; the energy can locally heat the surface of the material, melt it or make it vaporize. The vaporization process stands the one used in the case of engraving.

For a solid-state laser – which emits at a wavelength of 1064 nm; the materials have a different absorption percentage of the laser beam. For example, aluminum absorbs about 5% of it while steel under the same conditions more than 30%. However, the absorption factor is not the only parameter to take into consideration for laser processing. It is necessary to keep in mind the melting temperature of the material itself.

We are in conditions in which a material with a low absorption – such as aluminum for example – but with a low melting temperature (585 ° C) works faster and more easily than a material with higher absorption but at the same time with higher melting temperature, such as steel.

3) The resulting surface determines the effect of the marking;

During the marking process, a localized variation occurs on the surface hit by the laser beam. In this way, the surface roughness is altered and permanent signs are generated; which are the content of the marking: a code, a logo, a graphic.

By varying the laser parameters it is possible to obtain different roughnesses which – for the final marking effect – generate different colors. Where the surface roughness obtained causes the light rays to be reflected at different angles, i.e. in a diffused manner, the marking appears white.

On the other hand, when the surface roughness produces the effect of trapping the light rays, that is, absorbing them, the marking appears black.

Leave a Reply