Laser Engraving vs CNC Engraving Difference; Laser engraving is a high-precision process that when performed at professional quality, offers a well-optimized visual presentation and user efficiency. However, many businesses and users teeter between CNC engraving and laser. Do you know about the Plastic Depot; A laser engraving device commonly consists of a laser, a controller, and a surface. On the other hand, A CNC milling machine can also use as a CNC engraving device.

Here are the articles to explain, the Difference between Laser Engraving vs CNC Engraving!

Laser Engraving is often used in equal sentences as Laser Cutting, however, what exactly is Laser Engraving? How does it paint, which benefits does this technology have, and what substances can be used? This manual will solve all of these questions and offer a detailed evaluation. Are you equipped to dive into the sector of Laser Engraving?

CNC engraving gadget is a sort of equipment often utilized in diverse industries, mainly used for embossing, flat carving, and hollowing out wooden doorways, fixtures, metallic, acrylic, and so forth. As properly as engraving aluminum plates, stainless steel plates, PVC/PP plates, plastics, composite plates, and so on. Mainly consist of woodworking engraving machines, stone engraving machines, advertising engraving machines, laser engraving machines, glass engraving machines, plasma engraving machines, and laser slicing machines.

What is Laser Engraving?

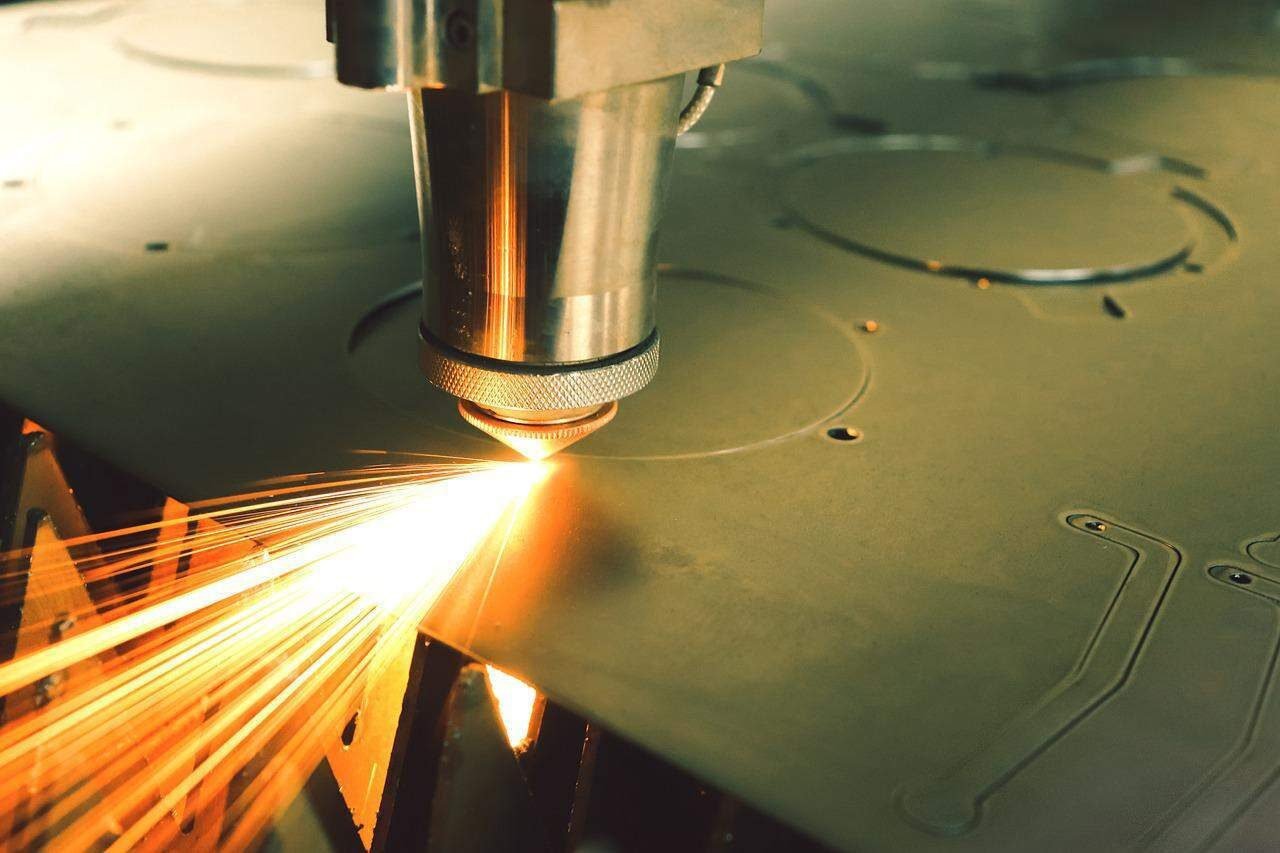

The laser marking procedure exists used to engrave permanent marks on special forms of substances. In this process, a laser engraving gadget vaporizes a specific region of the preferred element or cloth in a given pattern made by way of lasers, which includes CO2 or fiber lasers. This effects in an excessive-evaluation physical modification of the surface that stands easily seen to the bare eye.

Laser engraving paintings stand used to engrave logos, barcodes, serial or component numbers, or even QR codes. The technique is popular due to its high reliability; as well as the engraving’s permanent nature; which assures traceability and identification of the element or cloth in question for an extended duration.

Lasers and their packages have come a long way from virtually being an idea to a groovy element you could see in films and indicates. Today, lasers may use in so many matters; it’s greater than just a light source now, it may use to reduce and engrave. So, what’s laser engraving?

Breaking the words down, a laser is an item that produces or emits a slender beam of mild. Meanwhile, engraving is a technique to imprint an item thru slicing or carving. So through definition, laser engraving is an exercise or technique to engrave objects using lasers.

What is CNC Engraving?

When you need to manufacture a batch of products with the emblem call or artwork with prints, the use of engraving is a good answer. Combing with the development of producing equipment and gadget, right here we’re going to define CNC engraving. What is CNC engraving and what machines stand used? Check out the engraving gadget sorts and strategies applied.

Engraving is a cutting approach or process of carving a design into a tough floor, to decorate or label the items made of various materials; usually, the use of a fixed hand engraving equipment in the beyond, however CNC engraving is likewise exists had now. CNC engraving makes use of laptop-controlled machines; which regularly apply the milling paths generated through CAD-CAM software primarily based on the design drawing. Compared to guide engraving machines, CNC engraving machines; which lessen mistakes and enhance velocity, can do various sophisticated precision engraving, whether for sensible or creative purposes.

Here are a few tips to ensure you maintain the highest quality products and maximize your workplace production in an affordable, efficient manner.

Laser engraving projects;

The versatility of your project expectations will depend on the material choice. Two-tone plastics are one of our bread and butter materials, while we can also operate with metal. In the case of metal projects, 3D images can stand better represented with a bit more precision through laser engraving. CNC engraving will operate similarly, there’s just that added level of detail and precision when it comes to laser engraving.

Efficiency and getting a quick turnaround;

Laser engraving is a great route to also improve the turnaround on projects. Whether it be for work in bulk or a smaller load; you’ll see dividends paid in how quickly you can move on to the next steps.

Is it necessary the entire piece remains legible?

Of course, the expectation is that all etchings and engravings stand made to stay legible. However, you are likely pursuing engraving because you expect your pieces to be under duress from harsher conditions. Processing treatments are huge contributors to the legibility and potentially harm the original piece; which is a major reason why many designers elect to go with laser engraving primarily.

If you have questions on how to proceed with your project expectations and what standard your engraving will stand made at, we’d love to speak with you. We can customize our services and offers to ensure; that you are getting the right information and service for your work. We’re looking forward to speaking with you soon!