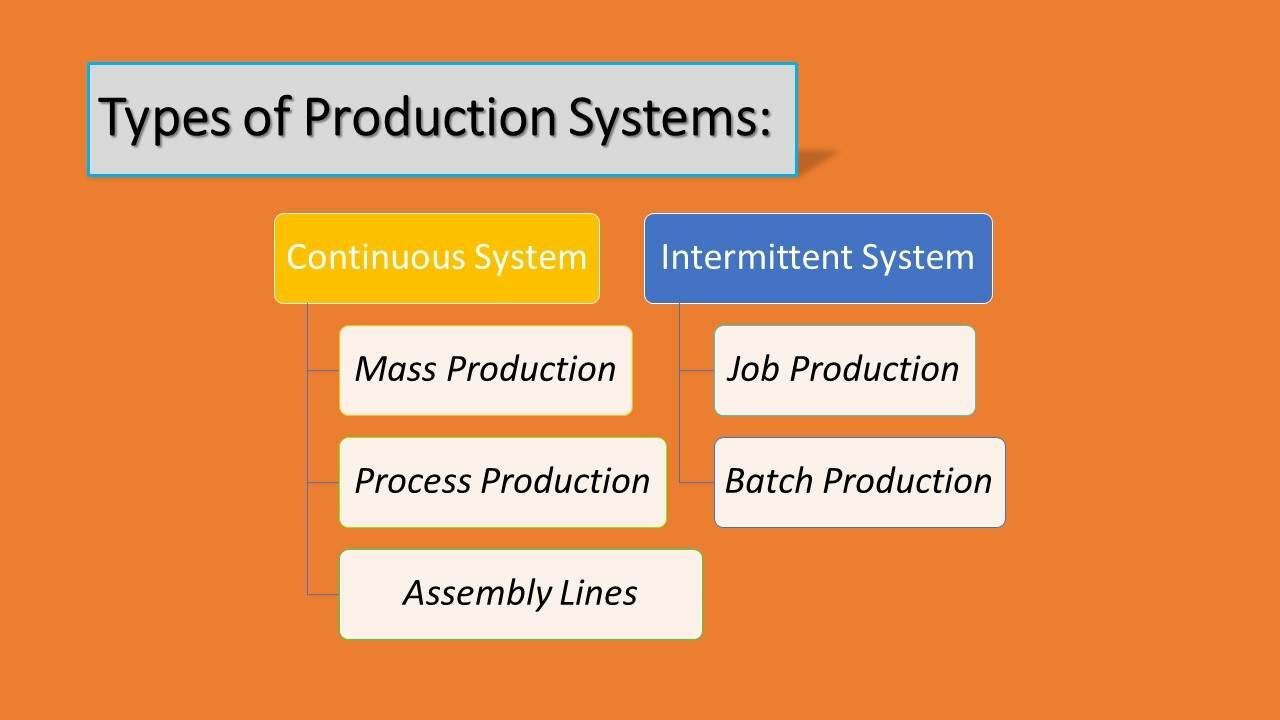

Types of Production Systems; A production manager will have to choose the most appropriate method for his enterprise. The final decision regarding any particular method of production is very much affecting by the nature of the products and the quantity to produce. The types of Production Systems are grouped under two categories viz., Intermittent production system, and Continuous production system.

Here are explain Types of Production Systems; Continuous System and Intermittent System with their advantage and disadvantage.

There are two main types of production systems: 1) Continuous System and 2) Intermittent System.

Continuous System or Flow System:

According to Buffa,

“Continuous flow production situations are those where the facilities are standardized as to routings and flow since inputs are standardized. Therefore a standard set of processes and sequences of the process can adopt.”

Thus continuous or flow production refers to the manufacturing of large quantities of a single or at most a very few varieties of products with a standard set of processes and sequences. The mass production is carried on continuously for stock in anticipation of demand.

Characteristics of Continuous System:

The following characteristics below are;

- The volume of output is generally large (mass production) and goods are produced in anticipation of demand.

- The product design and the sequence of the operations are standardized i.e. identical products are produced.

- Special purpose automatic machines are used to perform standardized operations.

- Machine capacities are balanced so that materials are fed at one end of the process and the finished product is received at the other end.

- Fixed path materials handling equipment is used due to the predetermined sequence of operations.

- Product layout designed according to a separate line for each product is considered.

Advantages of Continuous System:

The following advantages below are;

- The main advantage of the continuous system is that work-in-progress inventory is minimum.

- The quality of output is kept uniform because each stage develops skill through repetition of work.

- Any delay at any stage is automatically detected.

- Handling of materials is reduced due to the set pattern of the production line. Mostly the materials are handled through conveyor belts, roller conveyors, pipelines, overhead cranes, etc.

- Control over materials, cost, and output are simplified.

- The work can be done by semi-skilled workers because of their specialization.

The disadvantages of Continuous System:

The continuous system, however, is very rigid and if there is a fault in one operation the entire process is disturbed. Due to continuous flow, it becomes necessary to avoid piling up of work or any blockage on the line. Unless the fault is cleared immediately, it will force the preceding as well as the subsequent stages to be stopped. Moreover, it is essential to maintain stand by equipment to meet any breakdowns resulting in production stoppages. Thus investments in machines are fairly high.

Types of Continuous System:

Continuous production is of the following types;

Mass Production:

This production refers to the manufacturing of standardized parts or components on a large scale. Mass production system offers economies of scale as the volume of output is large. Quality of products tends to be uniform and high due to standardization and mechanization. In a properly designed and equipped process, individual expertise plays a less prominent role.

Process Production:

Production is carried on continuously through a uniform and standardized sequence of operations. Highly sophisticated and automatic machines are used. Process production is employed in the bulk processing of certain materials. The typical processing Industries are fertilizers plants, petrochemical plants, and milk dairies which have highly automated systems and sophisticated controls.

They are not labor-intensive and the worker is just an operator to monitor the system and take corrective steps if called for. On the basis of the nature of the production process, flow production may classify into Analytical and Synthetic Production.

- Analytical Process: In the Analytical Process of production, the raw material is broken into different products e.g. crude oil is analyzed into gas, Naptha, petrol, etc. Similarly, coal is processed to obtain coke, coal gas, coal tar, etc.

- Synthetic Process: Synthetic Process of production involves the mixing of two or more materials to manufacture a product, for instance, lauric acid, myristic acid, stearic acid are synthesized to manufacture soap.

Assembly Lines:

Assembly line a type of flow production which is developed in the automobile industry in the USA. A manufacturing unit prefers to develop and employ an assembly line because it helps to improve the efficiency of production. In an assembly line, each machine must directly receive material from the previous machine and pass it directly to the next machine.

Machine and equipment should be arranged in such a manner that every operator has free and safe access to each machine. Space should be provided for free movement of forklifts, trucks, etc. which deliver materials and collect finished products.

Intermittent System:

According to Buffa,

“Intermittent situations are those where the facilities must be flexible enough to handle a variety of products and sizes or where the basic nature of the activity imposes a change of important characteristics of the input (e.g. change. in the product design). In instances such as these, no single sequence pattern of operations is appropriate, so the relative location of the operation must be a compromise that is best for all inputs considered together.”

In the industries following the intermittent production system, some components may be made for inventory but they are combined differently for different customers. The finished product is heterogenous but within a range of standardized options assembled by the producers. Since production is partly for stock and partly for consumer demand, there are problems to be met in scheduling, forecasting, control, and coordination.

Characteristics of Intermittent System:

The following characteristics below are;

- The flow of production is intermittent, not continuous.

- The volume of production is generally small.

- A wide variety of products are produced.

- General purpose, machines, and equipment are used so as to be adaptable to a wide variety of operations.

- No single sequence of operations is used and periodical adjustments are made to suit different jobs or batches.

- Process layout is most suited.

The intermittent system is much more complex than continuous production because every product has to be treated differently under the constraint of limited resources.

The intermittent system can be-effective in situations which satisfy the following conditions:

- The production centers should be located in such a manner so that they can handle a wide range of inputs.

- Transportation facilities between production centers should be flexible enough to accommodate a variety of routes for different inputs.

- It should be provided with the necessary storage facility.

Types of Intermittent System:

Intermittent Production May be of two types;

Job Production:

Job or unit production involves the manufacturing of a single complete unit with the use of a group of operators and process as per the customer’s order. This is a “special order” type of production. Each job or product is different from the other and no repetition is involved. The product is usually costly and non-standardised.

Customers do not make a demand for exactly the same product on a continuing basis and therefore production becomes intermittent. Each product is a class by itself and constitutes a separate job for the production process. Shipbuilding, electric power plant, dam construction, etc. are common examples of job production.

Characteristics of Job Production:

- The product manufactured is custom-made or non-standardised.

- The volume of output is generally small.

- Variable path materials handling equipment are used.

- A wide range of general-purpose machines like grinders, drilling, press, shaper, etc. is used.

Advantages of Job Production:

It is flexible and can adapt easily to changes in product design. A fault in one operation does not result in complete stoppage of the process. Besides, it is cost-effective and time-effective since the nature of the operations in a group is similar. There is reduced material handling since machines are close in a cell. The waiting period between operations is also reduced. This also results in a reduced work-in-progress inventory.

The disadvantages of Job Production:

Job shop manufacturing is the most complex system of production e.g. in building a ship thousands of individual parts must be fabricated and assembled. A complex schedule of activities is required to ensure the smooth flow of work without any bottlenecks. Raw materials and work-in-progress inventories are high due to uneven and irregular flow of work. Workloads are unbalanced, speed of work is slow and unit costs are high.

Batch Production:

Batch production pertains to repetitive production. It refers to the production of goods, the quantity of which is known in advance. It is that form of production where identical products are produced in batches on the basis of demand of customers’ or of expected demand for products.

This method is generally similar to job production except for the quantity of production. Instead of making one single product as in case of job production, a batch or group of products are produced at one time. It should be remembered here that one batch of products may not resemble with the next batch.

It is defined as,

“The manufacture of a product in small or large batches or lots at intervals by a series of operations, each operation being carried out on the whole batch before any subsequent operation is performed.”

The batch production is a mixture of mass production and job production. Under it machines turn out different products at intervals, each product being produced for a comparatively short time using mass-production methods. Both job production and batch production are similar in nature, except that in batch production the quantity of product manufactured is comparatively large.

Advantages of Batch Production:

The batch production method possesses the following advantages;

- The work is of a repetitive nature.

- There is a functional layout of various manufacturing processes.

- One operation is carried out on the whole batch and then is passed on to the next operation and so on.

- The same type of machines is arranged at one place.

- It is generally chosen where trade is seasonal or there is a need to produce a great variety of goods.

The disadvantages of Batch Production:

Work-in-progress inventory is high and large storage space is required. Due to frequent changes in product design, no standard sequence of operation can be used. Machine set-ups and tooling arrangements have to be changed frequently. The main problem in batch production is the idle time between one operation and the other. The work has to wait until a particular operation is carried out on the whole batch.